Project Description

Development of a new type of polymer sleeves for the repair and rehabilitation of underground piping without digging

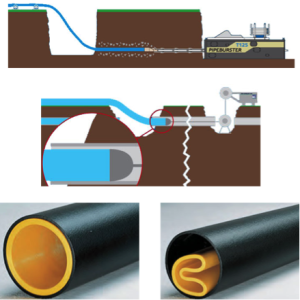

In the construction sector an important issue related to the downsides, difficulties and discomforts associated with the traditional laying, and especially the repair and rehabilitation, of any type of pipes or ducts.

The repair/rehabilitation of ducts has been carried out traditionally through a method based on trench digging.

The method based on trenches in urban centres or places with heavy traffic, has enormous repercussion, downsides and discomforts on the daily transitioning of these areas, as it involves road cutting and driveways and sidewalks elevation. In short, it can seriously affect the daily transit in these locations.

A solution that the sector brings to this discomforts, downsides or difficulties has been the use of sleeves. Through a traction system these sleeves are passed through the leaking pipes that are pending repair. Afterwards, air is injected in the sleeves to inflate them and get them stuck to the pipe walls. In this way the pipe is sealed and becomes operational again.

The objectives that OCIDE has set for the development of the project are as follows:

- Development of a type of sleeves that can allow the pipe repair/rehabilitation in those locations that are currently considered unfeasible.

- Investigate and gain more knowledge on the materials that the sleeves are made of, which will help in creating less thick types of sleeves without compromising their mechanical characteristics and final usability.

- OCIDE´s ultimate intention for the fulfilment of the Project, apart from developing a new type of sleeves for pipe repair, is also to develop a work methodology that can adjust to the needs and specificities of the pipelines subject to rehabilitation.

Comments are closed.